Scientists at the University of Texas at Dallas have created advanced carbon nanotube wires that can turn mechanical movement into electricity with exceptional efficiency. These yarns, known as twistrons, exhibit a conversion efficiency of 17.4% when stretched and 22.4% when twisted.

A team of researchers at UT Dallas first introduced Twistrons in 2017, driven by the growing need for a small, battery-free power supply in electronic devices. They created energy collectors using carbon nanotube threads, which are incredibly thin at 10,000 times smaller than a human hair, that generate electricity through movement, twist and pull.

The manufacturing process of “Twistrons” involves spinning carbon nanotubes to create lightweight, durable fibers that can incorporate electrolytes. These fibers can be incorporated into textiles, allowing them to capture energy from human movement, and even from wave motion in the ocean. To generate electricity, the fibers must be coated with an ionically conductive material called electrolyte. When the fibers are twisted or stretched, it decrease the volume, bringing the electrical charges closer to the wire, which increases the voltage stored in the wire.

A new method of winding

The researchers previously achieved a peak electrical power output of 250 watts per kilogram by stretching Twistrons 30 times per second. To accomplish this, they introduced a high level of twist to the wires, making them extremely elastic, similar to an over-twisted rubber band.

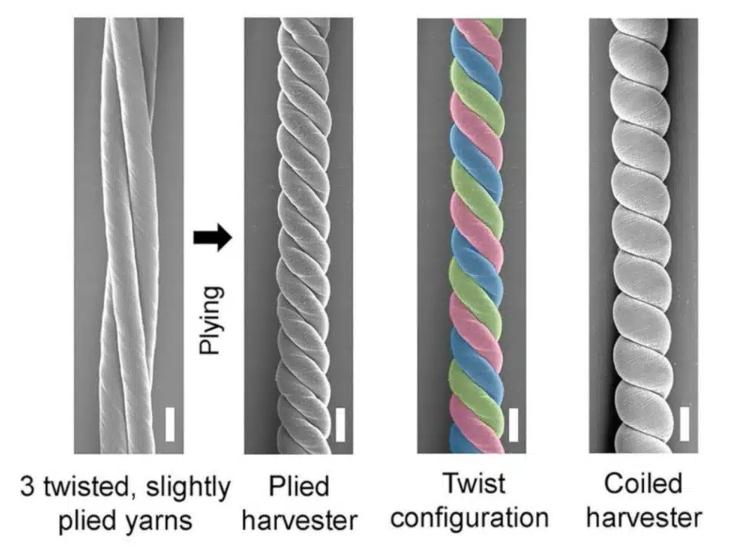

The team in the new study revealed how they were able to significantly enhance the efficiency of their Twistrons. Instead of using a single fiber of carbon nanotubes, they interwove three individual strands to form a single yarn, similar to the way wool or cotton yarns are created in the textile industry.

According to Dr. Ray Baughman, director of the Alan G. MacDiarmid NanoTech Institute at UT Dallas and corresponding author of the study, traditional twisted yarns in textiles are made by twisting individual strands in one direction and then twisting them together in the opposite direction to create the final yarn. This structure, known as heterochiral, provides stability against untwisting. In contrast, the researchers in this study employed a homochiral structure, in which the three strands were twisted together in the same direction.

The team reports that, by “braiding” the new wires, they have achieved higher gravimetric peak power and average power than any other material-based mechanical energy collector in the frequency range between 2 and 120 Hz.

Up to three times higher energy conversion efficiency

The team of researchers conducted various experiments to test the effectiveness of their three-stranded Twistrons. One such experiment involved attaching a Twistron between a balloon and the bottom of an aquarium filled with saltwater, as a way to mimic the generation of electricity from ocean waves.

A lattice made of several twistrons, weighing only 3.2 milligrams, was stretched repeatedly to charge a supercapacitor. This provided enough energy to power five small light-emitting diodes, a digital watch, and a digital humidity and temperature sensor.

The team also embedded twistrons into a cotton patch and placed it on a person’s elbow. As the person bent their elbow repeatedly, electrical signals were generated, suggesting that these high-tech wires could be used to harness the energy of human movement.

Previous versions of the twistrons had a maximum energy conversion efficiency of 7.6% for both tension and torsion, but the new twistrons have proven to be much more efficient. The team reports an efficiency of 17.4% for tensile energy collection and 22.4% for torsion energy collection.

What is the reason for these exceptional performances? According to Baughman, it is due to the additional mechanisms that allow for energy collection from lateral deformations when stretching or twisting the wire. When the three strands are brought into contact with each other, it seems to affect the electrical properties of the wire.

“When stretched, the wire becomes denser instead of less dense which results in carbon nanotubes becoming closer together, and this contributes to their ability to capture energy,” says the researcher.

The team has not yet determined the reasons why the three-strand structure provided the best results, however, they have filed a patent application for this technology.